- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

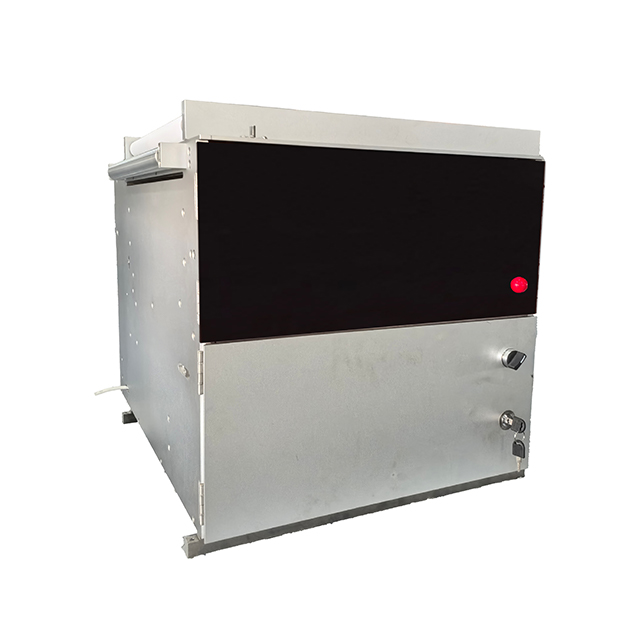

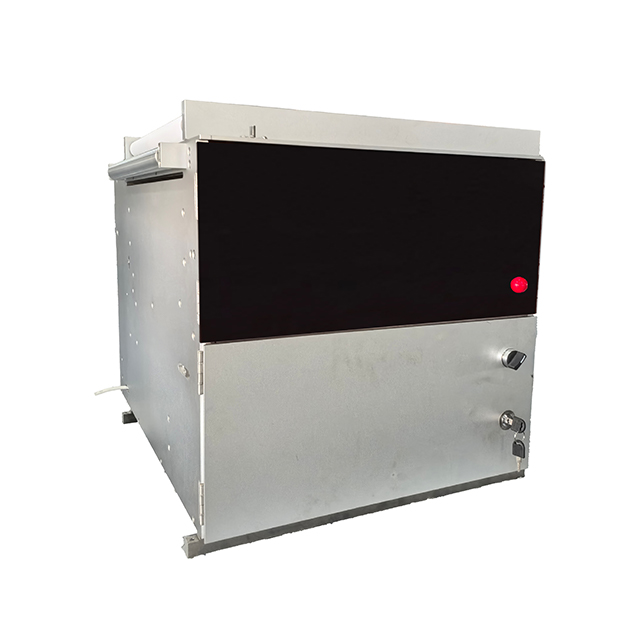

This ,printing machine features a compact design, easy installation, operation, and maintenance, high production efficiency, advanced automation, and superior print quality: It can operate independently or perform integrated cyclic printing under the control of a packaging machines automatic system,achieving automatic synchronization adjustment with the packaging machine.

| Availability: | |

|---|---|

| Quantity: | |

The RYS-Plate Printing Machine is a specialized printing equipment designed for the medical packaging industry, especially optimized for blister packaging applications. It integrates compact design with advanced automation, enabling seamless compatibility with both domestic and international blister packaging machines. Whether operating independently or as part of an integrated cyclic printing system controlled by a packaging machine’s auto-system, it ensures precise and high-quality printing, making it a core component for medical device manufacturers seeking to enhance production efficiency.

Compact & User-Friendly Design: Easy to install, operate, and maintain, saving workshop space and reducing labor costs for equipment management.

High Production Efficiency: Achieves 12-14 automatic cycles per minute, synchronized with the packaging machine’s paper feed to avoid production bottlenecks.

Superior Print Quality: Delivers consistent, clear prints, meeting strict quality standards for medical packaging labeling.

Strong Compatibility: Customizable specifications based on user-specific printing plate dimensions, adapting to diverse blister packaging needs.

Cost-Effective Consumables: Offers specialized inks at only 1/5 the price of comparable products, significantly cutting long-term operational costs.

Parameter | Details |

Power Supply | 220V (±10%), 50/60Hz |

Power Consumption | 80W |

Air Supply Pressure | 0.5-0.6MPa |

Air Consumption | 300NL/Min |

Maximum Printing Length | 400mm |

Maximum Printing Width | 400mm |

Efficiency | 12-14 cycles/min (automatically synchronized with packaging machine) |

Automatic Synchronization: Equipped with a smart adjustment system that realizes real-time synchronization with packaging machines, eliminating manual alignment errors and ensuring continuous production.

Durable Construction: Adopts high-quality materials for key components, ensuring stable operation even in long-hour (24/7) medical production environments.

For medical device manufacturers producing blister-packaged products (e.g., syringes, medical dressings):

Solves the pain point of "disconnected printing and packaging processes" by integrating directly with existing blister packaging lines, reducing production downtime.

Addresses small-batch, multi-specification production needs via customizable printing plates, avoiding the cost of replacing entire printing systems for different products.

The RYS-Plate Printing Machine’s structure is optimized for medical packaging scenarios:

Printing Mechanism: Uses a precision plate clamping system to fix printing plates securely, ensuring no plate displacement during high-speed operation—critical for consistent labeling of medical products.

Control Panel: Features an intuitive touchscreen interface, allowing operators to set printing parameters (speed, pressure) and monitor operation status at a glance, minimizing training time.

Ink Supply System: A dedicated ink circulation module ensures uniform ink distribution, preventing ink clotting and ensuring smooth printing even for long production runs.

Installation & Commissioning: Free on-site installation guidance and equipment commissioning to ensure the machine integrates smoothly with your existing production line.

Maintenance Training: Customized training sessions for your technical team, covering daily maintenance (e.g., ink system cleaning, component inspection) to extend equipment lifespan.

Customization Service: Tailored printing plate size adjustments and ink formula optimization based on your specific packaging materials (e.g., PVC, PET blister films).

Spare Parts Supply: A global spare parts warehouse ensures fast delivery of critical components (e.g., ink nozzles, air pressure valves) to minimize production downtime.

The RYS-Plate Printing Machine is a specialized printing equipment designed for the medical packaging industry, especially optimized for blister packaging applications. It integrates compact design with advanced automation, enabling seamless compatibility with both domestic and international blister packaging machines. Whether operating independently or as part of an integrated cyclic printing system controlled by a packaging machine’s auto-system, it ensures precise and high-quality printing, making it a core component for medical device manufacturers seeking to enhance production efficiency.

Compact & User-Friendly Design: Easy to install, operate, and maintain, saving workshop space and reducing labor costs for equipment management.

High Production Efficiency: Achieves 12-14 automatic cycles per minute, synchronized with the packaging machine’s paper feed to avoid production bottlenecks.

Superior Print Quality: Delivers consistent, clear prints, meeting strict quality standards for medical packaging labeling.

Strong Compatibility: Customizable specifications based on user-specific printing plate dimensions, adapting to diverse blister packaging needs.

Cost-Effective Consumables: Offers specialized inks at only 1/5 the price of comparable products, significantly cutting long-term operational costs.

Parameter | Details |

Power Supply | 220V (±10%), 50/60Hz |

Power Consumption | 80W |

Air Supply Pressure | 0.5-0.6MPa |

Air Consumption | 300NL/Min |

Maximum Printing Length | 400mm |

Maximum Printing Width | 400mm |

Efficiency | 12-14 cycles/min (automatically synchronized with packaging machine) |

Automatic Synchronization: Equipped with a smart adjustment system that realizes real-time synchronization with packaging machines, eliminating manual alignment errors and ensuring continuous production.

Durable Construction: Adopts high-quality materials for key components, ensuring stable operation even in long-hour (24/7) medical production environments.

For medical device manufacturers producing blister-packaged products (e.g., syringes, medical dressings):

Solves the pain point of "disconnected printing and packaging processes" by integrating directly with existing blister packaging lines, reducing production downtime.

Addresses small-batch, multi-specification production needs via customizable printing plates, avoiding the cost of replacing entire printing systems for different products.

The RYS-Plate Printing Machine’s structure is optimized for medical packaging scenarios:

Printing Mechanism: Uses a precision plate clamping system to fix printing plates securely, ensuring no plate displacement during high-speed operation—critical for consistent labeling of medical products.

Control Panel: Features an intuitive touchscreen interface, allowing operators to set printing parameters (speed, pressure) and monitor operation status at a glance, minimizing training time.

Ink Supply System: A dedicated ink circulation module ensures uniform ink distribution, preventing ink clotting and ensuring smooth printing even for long production runs.

Installation & Commissioning: Free on-site installation guidance and equipment commissioning to ensure the machine integrates smoothly with your existing production line.

Maintenance Training: Customized training sessions for your technical team, covering daily maintenance (e.g., ink system cleaning, component inspection) to extend equipment lifespan.

Customization Service: Tailored printing plate size adjustments and ink formula optimization based on your specific packaging materials (e.g., PVC, PET blister films).

Spare Parts Supply: A global spare parts warehouse ensures fast delivery of critical components (e.g., ink nozzles, air pressure valves) to minimize production downtime.

| Power Supply | 220V (±10%),50/60Hz |

| Power Consumption | 80W |

| Air Supply Pressure | 0.5-0.6MPa |

| Air Consumption | 300NL/Min |

| Maximum Printing Length | 400mm |

| Maximum Printing Width | 400mm |

| Efficiency | 12-14 cycles/min (automatically)synchronized with the packaging machine' s paper |

| Power Supply | 220V (±10%),50/60Hz |

| Power Consumption | 80W |

| Air Supply Pressure | 0.5-0.6MPa |

| Air Consumption | 300NL/Min |

| Maximum Printing Length | 400mm |

| Maximum Printing Width | 400mm |

| Efficiency | 12-14 cycles/min (automatically)synchronized with the packaging machine' s paper |