- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

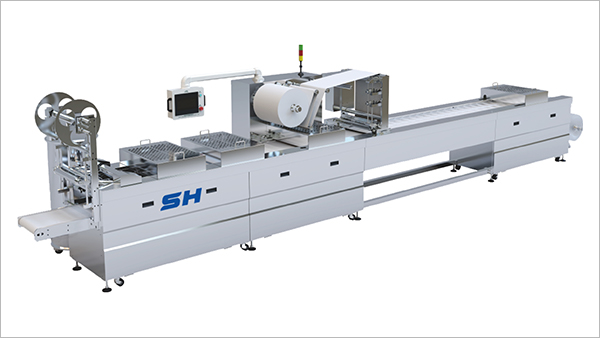

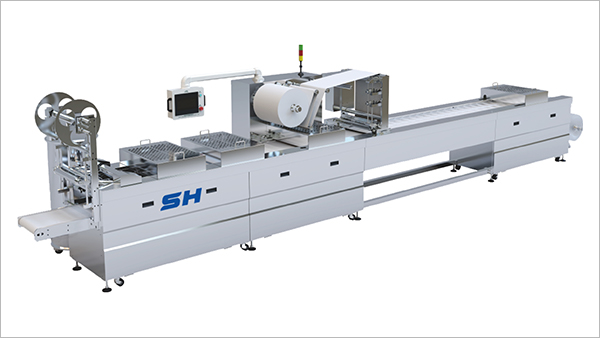

This equipment is suitable for both flexible and rigid film thermoforming packaging, retaining all functionsof standard PZB packagingmachines while offering enhanced product adaptability. Key technical features indlude:Rear-tilted chain traction system-Ensures reliable operation and extended service life.Integrated punching/cutting mechanism-Creates smooth rounded corners on products.Floating compression cylinder for heat sealing - Delivers uniform surface flatness.

| Availability: | |

|---|---|

| Quantity: | |

The RY-Universal Packing Machine by SH Shenghe Electromechanical bridges the gap between specialized packaging machines: it handles both flexible (e.g., PE films) and rigid (e.g., PET) films, while retaining all functions of standard PZB machines. Key innovations—like the rear-tilted chain traction system and floating compression cylinder—ensure reliability, precision, and compatibility with industry-standard processes. It is ideal for medical devices, electronics, cosmetics, and food, where diverse packaging needs demand flexibility.

Dual Film Compatibility: Works with flexible and rigid films, eliminating the need for separate machines.

Enhanced Durability: Rear-tilted chain traction reduces wear, extending service life by 30% vs. traditional systems.

Smooth Finishing: Integrated punching/cutting creates rounded corners, improving safety and aesthetics.

Uniform Sealing: Floating compression cylinder ensures flat, airtight seals—critical for sterile or moisture-sensitive products.

Consistent Thermoforming: Variable-speed punching head maintains even film thickness, avoiding weak spots.

Specification | Details |

Maximum Packing Width | 400mm |

Maximum Packing Length | 320mm |

Maximum Forming Depth | 80mm |

Power Supply | 18KW (380V/50HZ/3P+N+PE) |

Rated Pressure | 20.6MPa |

Cooling Water Requirement | >5L/min, <25℃ |

Machine Weight | Abt. 2.5T |

Key Mechanisms | Rear-tilted chain traction, integrated punching/cutting, floating compression cylinder |

The dual film compatibility is a game-changer for manufacturers with diverse product lines. For example, a cosmetic brand can use rigid films for premium skincare jars and flexible films for sample sachets—all with one machine. The rear-tilted chain traction system ensures smooth film feeding, reducing waste by 15% (vs. machines with slipping issues). The floating compression cylinder adapts to minor film thickness variations, ensuring consistent seals even for uneven materials.

Medical Device Packaging: Uses rigid films to protect sterile tools (e.g., syringes) and flexible films for conformable packaging of delicate components. Rounded corners prevent package tearing in transit.

Electronics: Rigid films shield components from moisture/dust, while the airtight seal maintains product integrity during shipping.

Cosmetics: Switches between rigid films (for luxury lipstick cases) and flexible films (for face mask pouches) to support brand diversity.

The rear-tilted chain is made of high-strength stainless steel, with precision gears to prevent slippage. It requires minimal lubrication, reducing maintenance costs, and is easily accessible for cleaning.

The floating compression cylinder uses air pressure to apply uniform force across the seal area—even if the film has slight thickness variations. Sealing temperature (120–230℃) and pressure are adjustable via a touchscreen, supporting films from 50μm to 200μm thick.

The integrated mechanism uses tungsten carbide blades for clean cuts and rounded corners. Blades are replaceable in 10 minutes, and the system is synchronized with thermoforming to ensure package dimensions are consistent (±0.5mm).

Film Compatibility Testing: Tests client-supplied films (flexible/rigid) to optimize machine parameters, avoiding waste.

Line Integration: On-site engineers integrate the RY Machine with upstream (filling) and downstream (labeling) equipment.

Training Programs: Customized training for operators (basic operation) and technicians (advanced maintenance).

Upgrade Services: Offers retrofits (e.g., adding barcode scanners) to adapt the machine to evolving production needs.

The RY-Universal Packing Machine by SH Shenghe Electromechanical bridges the gap between specialized packaging machines: it handles both flexible (e.g., PE films) and rigid (e.g., PET) films, while retaining all functions of standard PZB machines. Key innovations—like the rear-tilted chain traction system and floating compression cylinder—ensure reliability, precision, and compatibility with industry-standard processes. It is ideal for medical devices, electronics, cosmetics, and food, where diverse packaging needs demand flexibility.

Dual Film Compatibility: Works with flexible and rigid films, eliminating the need for separate machines.

Enhanced Durability: Rear-tilted chain traction reduces wear, extending service life by 30% vs. traditional systems.

Smooth Finishing: Integrated punching/cutting creates rounded corners, improving safety and aesthetics.

Uniform Sealing: Floating compression cylinder ensures flat, airtight seals—critical for sterile or moisture-sensitive products.

Consistent Thermoforming: Variable-speed punching head maintains even film thickness, avoiding weak spots.

Specification | Details |

Maximum Packing Width | 400mm |

Maximum Packing Length | 320mm |

Maximum Forming Depth | 80mm |

Power Supply | 18KW (380V/50HZ/3P+N+PE) |

Rated Pressure | 20.6MPa |

Cooling Water Requirement | >5L/min, <25℃ |

Machine Weight | Abt. 2.5T |

Key Mechanisms | Rear-tilted chain traction, integrated punching/cutting, floating compression cylinder |

The dual film compatibility is a game-changer for manufacturers with diverse product lines. For example, a cosmetic brand can use rigid films for premium skincare jars and flexible films for sample sachets—all with one machine. The rear-tilted chain traction system ensures smooth film feeding, reducing waste by 15% (vs. machines with slipping issues). The floating compression cylinder adapts to minor film thickness variations, ensuring consistent seals even for uneven materials.

Medical Device Packaging: Uses rigid films to protect sterile tools (e.g., syringes) and flexible films for conformable packaging of delicate components. Rounded corners prevent package tearing in transit.

Electronics: Rigid films shield components from moisture/dust, while the airtight seal maintains product integrity during shipping.

Cosmetics: Switches between rigid films (for luxury lipstick cases) and flexible films (for face mask pouches) to support brand diversity.

The rear-tilted chain is made of high-strength stainless steel, with precision gears to prevent slippage. It requires minimal lubrication, reducing maintenance costs, and is easily accessible for cleaning.

The floating compression cylinder uses air pressure to apply uniform force across the seal area—even if the film has slight thickness variations. Sealing temperature (120–230℃) and pressure are adjustable via a touchscreen, supporting films from 50μm to 200μm thick.

The integrated mechanism uses tungsten carbide blades for clean cuts and rounded corners. Blades are replaceable in 10 minutes, and the system is synchronized with thermoforming to ensure package dimensions are consistent (±0.5mm).

Film Compatibility Testing: Tests client-supplied films (flexible/rigid) to optimize machine parameters, avoiding waste.

Line Integration: On-site engineers integrate the RY Machine with upstream (filling) and downstream (labeling) equipment.

Training Programs: Customized training for operators (basic operation) and technicians (advanced maintenance).

Upgrade Services: Offers retrofits (e.g., adding barcode scanners) to adapt the machine to evolving production needs.

content is empty!